Here are just a few:

Lab-Grown Diamond is identical in every way to natural mined diamonds except it’s origin, age and size.

Grown diamond has all the same intrinsic properties of natural diamond. The main benefit of grown diamond is the ability to have larger sizes and different shapes of diamond. 98% of natural diamonds come out of the earth in small pebble like sizes which are beneficial for some applications, but not normally for high Tech.

Electronics

Lab-grown diamond has potential uses as a semiconductor because it can be doped with impurities like boron and phosphorus. Since these elements contain one more or one fewer valence electron than carbon, they turn lab-grown diamond into p-type or n-type semiconductors. Making a p–n junction by sequential doping of lab-grown diamond with boron and phosphorus produces light-emitting diodes (LEDs) producing UV light of 235 nm. Another useful property of lab-grown diamond for electronics is high carrier mobility, which reaches 4500 cm2/(V·s) for electrons in single-crystal CVD diamond. High mobility is favorable for high-frequency operation and field-effect transistors made from diamond have already demonstrated promising high-frequency performance above 50 GHz. The wide band gap of diamond (5.5 eV) gives it excellent dielectric properties. Combined with the high mechanical stability of diamond, those properties are being used in prototype high-power switches for power stations.

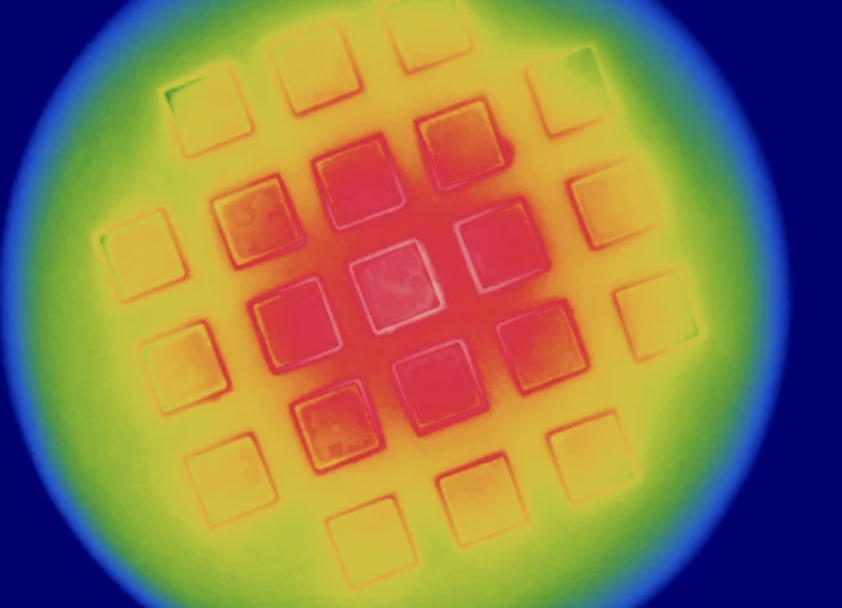

Thermal Conductivity

Most materials with high thermal conductivity are also electrically conductive, such as metals. In contrast, pure lab-grown diamond has high thermal conductivity, but negligible electrical conductivity. This combination is invaluable for electronics where diamond is used as a heat spreader for high-power laser diodes, laser arrays and high-power transistors. Efficient heat dissipation prolongs the life of those electronic devices, and the devices’ high replacement costs justify the use of efficient, though relatively expensive, diamond heat sinks. In semiconductor technology, synthetic diamond heat spreaders prevent silicon and other semiconducting devices from overheating.

Optics

Diamond is hard, chemically inert, and has high thermal conductivity and a low coefficient of thermal expansion. These properties make diamond superior to any other existing window material used for transmitting infrared and microwave radiation. Therefore, lab-grown diamond is starting to replace zinc selenide as the output window of high-power CO2 lasers and gyrotrons. Those lab-grown polycrystalline diamond windows are shaped as disks of large diameters (about 10 cm for gyrotrons) and small thicknesses (to reduce absorption) and can only be produced with the CVD technique. Single crystal slabs of dimensions of length up to approximately 10 mm are becoming increasingly important in several areas of optics including heatspreaders inside laser cavities, diffractive optics and as the optical gain medium in Raman lasers.